3M™ Boron Nitride Cooling Filler Agglomerates

- 3M ID B5005473000

Details

Highlights

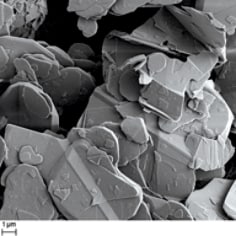

- Randomly orientated agglomerated single platelets for high through-plane thermal conductivity

- Delivers excellent heat dissipation for protection of sensitive components

- Isotropic heat transfer compared to platelets

- Soft bulk agglomerates adapt to matrix, helping maintain flexibility

- Excellent for conformable thermal interface materials (TIMs)

- High electrical insulation properties with low Dk and Df

3M™ Boron Nitride Cooling Filler agglomerates are randomly oriented agglomerates of crystalline boron nitride single platelets. Featuring excellent heat transfer capabilities, these agglomerates can help achieve much higher W/m*K vs. mineral or oxide fillers. Soft agglomerates adapt to the flexibility of the polymer matrix. 3M™ BN cooling filler agglomerates are especially good for thin thermal interface materials (TIMs) requiring consistent heat transfer and high through-plane conductivity.

-

Compound Viscosity Control

Compound Viscosity Control -

Conformability

Conformability -

Excellent Heat Dissipation

Excellent Heat Dissipation -

High Through-plane Conductivity

High Through-plane Conductivity

-

-

Excellent for through-plane conductivity

3M™ BN cooling filler agglomerates are a great choice for applications requiring high through-plane heat dissipation and consistent heat transfer. Randomly-oriented agglomerated platelets create isotropic thermal conductivity that performs even for very thin materials. Agglomerates are excellent for Thermal Interface Materials (TIMs) and other applications requiring dissipation of heat away from valuable components such as chips, LEDs, CPUs and EV battery cells.

A complete selection of 3M™ Boron Nitride Cooling Fillers includes platelets, flakes and agglomerates can meet a full range of performance specifications for in-plane and through-plane thermal conductivity.

Grades of 3M™ Boron Nitride Cooling Filler agglomerates:

-

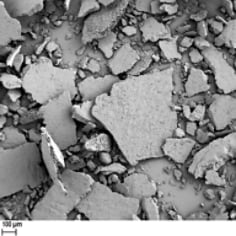

CFA 50MA mix (M) of agglomerates, platelets and boron nitride clusters is excellent for potting resins and encapsulation of electronic devices.

CFA 50MA mix (M) of agglomerates, platelets and boron nitride clusters is excellent for potting resins and encapsulation of electronic devices. -

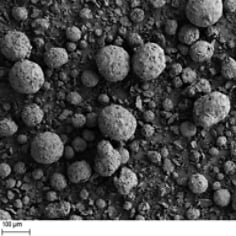

CFA 250SBoron nitride platelets are spray-dried with an inorganic binder to spherical (S) granulates for high flowability and dosing velocities during feeding. They are ideal for thermal interface management (TIM) pads.

CFA 250SBoron nitride platelets are spray-dried with an inorganic binder to spherical (S) granulates for high flowability and dosing velocities during feeding. They are ideal for thermal interface management (TIM) pads. -

CFA 150Soft agglomerates allow for high filler loadings and isotropic thermal conductivity. CFA 150 is used for potting resins and conformable TIM foils or pads with thin bond lines above 200 µm.

CFA 150Soft agglomerates allow for high filler loadings and isotropic thermal conductivity. CFA 150 is used for potting resins and conformable TIM foils or pads with thin bond lines above 200 µm. -

CFA 100Soft agglomerates deliver the same uses and benefits as CFA 150, but can be used for materials with thinner bond lines from 150-200 μm.

CFA 100Soft agglomerates deliver the same uses and benefits as CFA 150, but can be used for materials with thinner bond lines from 150-200 μm. -

CFA 75Soft agglomerates deliver the same uses and benefits as CFA 100, but can be used for materials with bond lines as thin as 100-150 μm.

CFA 75Soft agglomerates deliver the same uses and benefits as CFA 100, but can be used for materials with bond lines as thin as 100-150 μm.

Specifications

| Applications | Increasing Thermal Conductivity |

| Product Usage | Electronic Overmoldings, Potting Resins, TIM Pads, Greases, Gap Fillers, TIM Foils |

Resources

Data Sheets

(PDF, 2MB)

Connect with us. We’re here to help.

Send Us a Message

Thank you for your interest in 3M. In order to help us manage and respond to your query effectively, we politely ask you to provide some key information, including your contact details. The information you provide will be used to respond to your request through email or telephone by a 3M representative or one of our authorised business partners with whom we might share your personal information consistent with the 3M privacy policy

Thank you for your contacting 3M

We have received your message and are now looking into your enquiry

One of our representatives will get in touch with you by phone or email

bn-cooling-filler-agglomerates.pdf

bn-cooling-filler-agglomerates.pdf 3M™ Boron Nitride Cooling Filler Agglomerates

3M™ Boron Nitride Cooling Filler Agglomerates 3M™ Boron Nitride Cooling Filler Flakes

3M™ Boron Nitride Cooling Filler Flakes 3M™ Boron Nitride Cooling Filler Platelets

3M™ Boron Nitride Cooling Filler Platelets