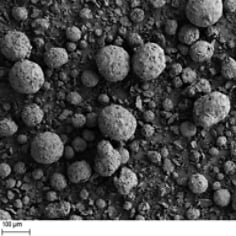

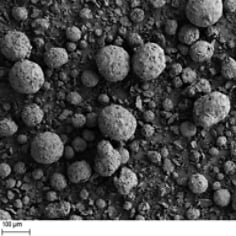

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000

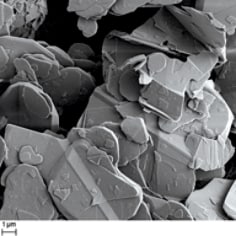

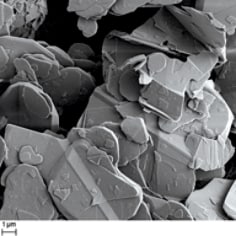

3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002

3M™ Boron Nitride Cooling Fillers do much more than just add thermal conductivity to resin systems. Meeting the increasing need for “smart” polymers, especially in electrified vehicles, 3M BN cooling fillers are helping enable a new generation of electrical and electronic components in automotive production.

This versatile family of ceramic fillers can functionally integrate thermal management into polymers, without affecting electrical insulation. The result is higher performing components and materials that can be used in more places in the vehicle. The possibilities are just beginning.

If you'd like to see more videos pertaining to specific applications and usage of 3M Boron Nitride Cooling Fillers in TPE compounds, TIM pads and overmoulding of electronic parts, visit our automotive education portal.

Raschig GmbH in cooperation with 3M: Read how thermoset injection molding of electronic components combines mechanical protection with effective thermal management.

Addressing challenges in thermal management, sustainability, and production efficiency.

Explore the potential of tailored thermal conductivity in direct injection molding (DIM) with epoxy-based thermoset compounds.

Discover how Kisling GmbH, a member of the Würth Group, elevates the performance of electronic components and enhances efficiency through the use of thermally conductive potting compounds.

Manufacturers of consumer and automotive electronics, high-capacity batteries, LED lighting, 5G applications and other electrical and electronic devices are increasingly utilising high-performance polymers to reduce component size and weight while simplifying assembly.

Learn more about thermally conductive fillers and how 3M Boron Nitride Cooling Fillers can boost the thermal conductivity of existing compounds, how processing factors influence performance, and more!

Explore the advantages of boron nitride over other fillers, including superior thermal conductivity, electrical insulation, and lubricity properties. Learn more about this versatile material and its potential applications.

xEVs - electromotive vehicles such as a hybrid or plug-in hybrid electric vehicles or fuel-cell electric vehicles - present new thermal challenges throughout the vehicle. In some applications, like power electronics, high heat needs to be dissipated from a small area. With an inherently high thermal conductivity, even a small amount of 3M Boron Nitride Cooling Fillers can boost the thermal conductivity of various polymers such as silicones, epoxies, and thermoplastics. 3M Boron Nitride Cooling Filler platelets, flakes, and agglomerates can be used to achieve either through-plane or in-plane heat dissipation, depending on your application needs.

With a material thermal conductivity of 400 w/mK in plane, 3M Boron Nitride Cooling Fillers is 8-20x more thermally conductive than alumina fillers (intrinsic) and 2 – 8x more thermally conductive when mixed in polymers.

Abrasive fillers can wear away at equipment being used to process the materials. Compared to other fillers, 3M Boron Nitride Cooling Fillers are one of the least abrasive. This softer material can minimise equipment wear which may help to extend your equipment lifetime.

As you add fillers to your polymer matrix to boost thermal conductivity, the viscosity of the matrix changes. 3M’s multiple cooling filler grades allow you to define the viscosity to optimize your formulation and tailor to your application need.

Compared to other ceramic fillers, 3M Boron Nitride Cooling Fillers provides the highest electrical resistivity at >10¹⁵ Ohm*cm³ with a high breakdown strength. Not only can you boost the thermal conductivity properties of your matrix, you can tackle multiple properties with this one filler by also making it more electrically insulating. This can help to shield more sensitive components and prevent unwanted arcing.

High electrical insulation and breakdown strength are main requirements for thin insulation foils.

With a low density of 2.25 g/cm³, adding 3M Boron Nitride Cooling Fillers to your compound will boost needed properties while keeping the compound density at 1.2 – 1.6 g/cm³.

The low compound density is favorable for housings or LED lamp sockets for example as higher weight aluminum parts can be replaced by the thermal conductive polymer.

In a 5G connected and autonomous driving world, vehicles will generate and process more data at higher speeds and frequencies. Sensors and other automotive electronic designs are smaller, higher-performing – and produce a lot more heat. Also, as signal transmission and frequencies increase, especially in the millimeter wave spectrum, the risk of signal loss intensifies. Managing these challenges will help improve automated driving system performance and reliability for increased safety on the road.

Demand for heat removal across the vehicle is growing as the performance demands on electronic components increases and as powertrains become more electrified. 3M BN cooling fillers can help by increasing the thermal conductivity of polymers such as silicones, epoxies and thermoplastics used to manage heat. These thermally conductive materials include potting resins, heat spreaders, glues, greases and insulation foils, as well as thermal interface material (TIM) foils and pads. 3M BN cooling fillers are also for injection molded thermoplastics used for housings and sockets.

Want to talk to a 3M expert to discuss your specific needs?

CONNECT WITH A 3M EXPERT

An error has occurred while submitting. Please try again or send an email to 3mautomotive_oem_and_tier@mmm.com

Please check your in-box for the case study you requested.

If you want to keep track of all of the trends and new solutions within the electric vehicle space. Let us do the hard work for you by sending you the topics you are most interested in. Click here to sign up today to access case studies, webinars and our application videos.

Filter

3M™ Boron Nitride Cooling Filler Agglomerates

3M Stock

B5005473000

3M™ Boron Nitride Cooling Filler Platelets

3M Stock

B5005473002