- Overview

- Products

- Respiratory Protection

- Hearing Protection

- Fire Safety

- Eye protection

- Head and Face Protection

- Welding Protection

- Protective Coveralls

- Fall Protection

- All Products

- Industry Solutions

- Metal Production & Fabrication

- Energy & Utilities

- Confined Space

- Defence PPE

- Construction Industry Solutions

- Healthcare Solutions & PPE

- Pharmaceutical Industry Solutions

- All Industries

- TRAINING

- Resources

- Genuine PPE

- PPE Safety News

- PPE Fit Validation

- PPE Selection & Use

- Guide to the PPE Regulation (EU) 2016 / 425

- Support

Helping Enhance Worker Health and Safety.

Quality PPE for Wastewater and Water Treatment Workers

Water treatment workers may not always realize it, but they can be exposed to a variety of hazards every day. These include working at height, biohazards and respiratory hazards – not only from the sewage and wastewater itself, but also from the chemicals used to treat it. Not to mention the unique hazards posed by working in confined or poorly ventilated spaces.

Education and the proper use of PPE are among the ways to help protect workers against these hazards at every step. 3M offers a comprehensive portfolio of quality personal protective equipment designed for comfort – and backed by over 50 years of experience in the science of safety.

Intake

Solids Separation

Primary Clarification

Primary Sedimentation

Chemical Treatment

Secondary Clarification

Final Sedimentation

As the need for clean water grows, so does the need for water treatment workers. With plant infrastructure aging and water costs rising, these workers are facing new pressures. The World Economic Forum ranks wastewater treatment work as eighth in a list of the ten most “unhealthy” jobs because of the risks:

- Biological: gastrointestinal and upper respiratory illnesses

- Physical: cuts, burns, blunt force injury, accidental drowning

- Chemical: irritation, injury or death from contact or inhalation

3M Solutions by Process

As the number of wastewater treatment facilities grows, so does the need to keep these critical workers safe on the job. Workers must not only be provided with quality PPE, but they must also be educated about its proper wear and use. With our comprehensive portfolio of PPE solutions – along with our library of training and education materials – 3M is your resource for safety at every step of the water treatment process.

Browse the following section to view potential risks, where they may be present, and how 3M PPE can help protect workers against the daily hazards of their jobs.*

*The following options do not reflect all required PPE for a given application or hazard. Reference and follow all local regulations.

-

Step 1: Intake

-

Pump station: While generally a closed process, routine maintenance can involve working in confined spaces

Source water: the type of biological, chemical and physical hazards present in wastewater – and the type of agents used to treat it – can differ based on the source of the water itself. Consider these examples of hazards that may be present:

- Sewage: bacteria, viruses, parasites in human waste

- Stormwater: physical hazards washed down drains

- Agricultural runoff: pesticides, fertilizer

- Manufacturing discharge: oil, corrosive chemicals

- Medical: pharmaceuticals, infectious diseases

-

Potential 3M PPE:

- Head Protection

- Protective Eyewear

- Hearing Protection

Pump station: While generally a closed process, routine maintenance can involve working in confined spaces

Source water: the type of biological, chemical and physical hazards present in wastewater – and the type of agents used to treat it – can differ based on the source of the water itself. Consider these examples of hazards that may be present:

- Sewage: bacteria, viruses, parasites in human waste

- Stormwater: physical hazards washed down drains

- Agricultural runoff: pesticides, fertilizer

- Manufacturing discharge: oil, corrosive chemicals

- Medical: pharmaceuticals, infectious diseases

-

Potential 3M PPE:

- Head Protection

- Protective Eyewear

- Hearing Protection

-

-

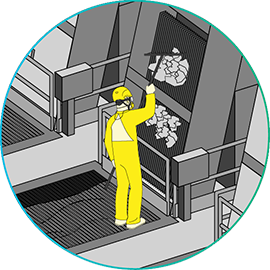

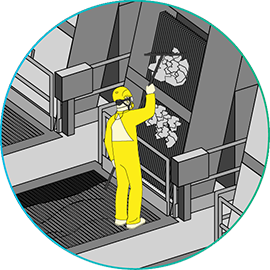

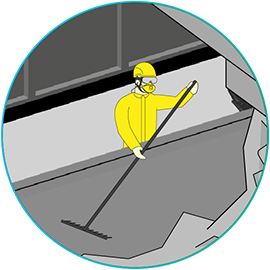

Step 2: Solids Separation

-

Bar screens: As large solids are removed from inflowing water, objects can become lodged in the equipment and require manual removal. At this point, workers can be exposed to direct contact with sewage and its biohazards. This is also the step where nuisance odors are most prominent. Disposable or reusable respirators may be beneficial for worker comfort, in addition to helping protect against exposure to possible airborne biological hazards.

Potential hazards:

- Physical: cuts on sharp objects, accidental injection (needles)

- Biological: skin and eye exposure to bacteria, viruses, fungi and parasites

- Airborne: strong nuisance odors

- Falls: reaching over the guard rail with a rake to remove clogged objects

- Noise: nuisance noise from machinery; communications could be desirable for ease of talking with control room operator or inter-team communications.

Bar screens: As large solids are removed from inflowing water, objects can become lodged in the equipment and require manual removal. At this point, workers can be exposed to direct contact with sewage and its biohazards. This is also the step where nuisance odors are most prominent. Disposable or reusable respirators may be beneficial for worker comfort, in addition to helping protect against exposure to possible airborne biological hazards.

Potential hazards:

- Physical: cuts on sharp objects, accidental injection (needles)

- Biological: skin and eye exposure to bacteria, viruses, fungi and parasites

- Airborne: strong nuisance odors

- Falls: reaching over the guard rail with a rake to remove clogged objects

- Noise: nuisance noise from machinery; communications could be desirable for ease of talking with control room operator or inter-team communications.

-

-

Step 3: Primary Clarification

-

Settling tanks, grit chambers and solids removal: After solids are separated out via aeration basin or settling tank, they are removed with an augur or conveyor and pumped into a dumpster or dump truck. Workers do not typically contact the wastewater material but may occasionally need to clear the bar grate. In that case, they may be exposed to biological splash hazards and hazardous foreign objects.

Potential hazards:

- Airborne: nuisance odors

- Biological: skin and eye exposure to bacteria, viruses, fungi and parasites

- Physical: cuts on sharp objects, accidental injection (needles)

- Falls: climbing dumpster or dump truck to move material

- Noise: nuisance noise from auger or conveyor; communications could be desirable for ease of talking with control room operator or inter-team communications

Settling tanks, grit chambers and solids removal: After solids are separated out via aeration basin or settling tank, they are removed with an augur or conveyor and pumped into a dumpster or dump truck. Workers do not typically contact the wastewater material but may occasionally need to clear the bar grate. In that case, they may be exposed to biological splash hazards and hazardous foreign objects.

Potential hazards:

- Airborne: nuisance odors

- Biological: skin and eye exposure to bacteria, viruses, fungi and parasites

- Physical: cuts on sharp objects, accidental injection (needles)

- Falls: climbing dumpster or dump truck to move material

- Noise: nuisance noise from auger or conveyor; communications could be desirable for ease of talking with control room operator or inter-team communications

-

-

Step 4: Primary Sedimentation

-

Clarifiers: There is less splash hazard here than in previous steps, because the agitation in the tank is very slow, and workers do not have to reach in with rakes to remove large solids. However, workers should still consider wearing their full set of PPE.

Potential hazards:

- Biological: skin and eye exposure to bacteria, viruses, fungi and parasites

- Physical: cuts on sharp objects, accidental injection (needles)

- Airborne: nuisance odors (less so than in Steps 2-3)

- Noise: nuisance noise from pump; communications could be desirable for ease of talking with control room operator or inter-team communications

Clarifiers: There is less splash hazard here than in previous steps, because the agitation in the tank is very slow, and workers do not have to reach in with rakes to remove large solids. However, workers should still consider wearing their full set of PPE.

Potential hazards:

- Biological: skin and eye exposure to bacteria, viruses, fungi and parasites

- Physical: cuts on sharp objects, accidental injection (needles)

- Airborne: nuisance odors (less so than in Steps 2-3)

- Noise: nuisance noise from pump; communications could be desirable for ease of talking with control room operator or inter-team communications

-

-

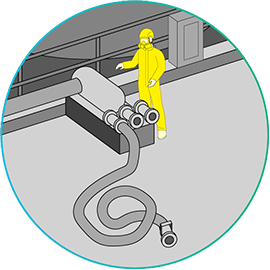

Step 5: Secondary Clarification

-

Chemical feed/aeration and biological reduction: Here, the hazard shifts from the wastewater itself to the hazards of the chemicals or bacteria added to treat it. Under normal operating conditions, these are closed systems designed to prevent worker exposure. However, certain tasks may involve handling of chlorine or other hazardous materials. Workers may be exposed to chemical splashes and sprays, for example, when they connect the piping between the tanker truck and storage tanks.

The required PPE will depend on the chemical or biological agents used – which in turn depends on the composition of the wastewater being treated. But many of these chemicals can cause significant injury via contact or inhalation. Some, like chlorine, can be deadly. Workers should be equipped with robust respiratory protection and have access to supplied air or escape breathing apparatus in case of emergency.

Potential hazards:

- Chemical: inhalation of gas/fumes, skin irritation or burns from contact with liquid

- Oxygen deprivation: emergency air supply should be available in case of accidental release

- Noise: nuisance noise from truck pumps; communications could be desirable for ease of talking with control room operator or inter-team communications

Chemical feed/aeration and biological reduction: Here, the hazard shifts from the wastewater itself to the hazards of the chemicals or bacteria added to treat it. Under normal operating conditions, these are closed systems designed to prevent worker exposure. However, certain tasks may involve handling of chlorine or other hazardous materials. Workers may be exposed to chemical splashes and sprays, for example, when they connect the piping between the tanker truck and storage tanks.

The required PPE will depend on the chemical or biological agents used – which in turn depends on the composition of the wastewater being treated. But many of these chemicals can cause significant injury via contact or inhalation. Some, like chlorine, can be deadly. Workers should be equipped with robust respiratory protection and have access to supplied air or escape breathing apparatus in case of emergency.

Potential hazards:

- Chemical: inhalation of gas/fumes, skin irritation or burns from contact with liquid

- Oxygen deprivation: emergency air supply should be available in case of accidental release

- Noise: nuisance noise from truck pumps; communications could be desirable for ease of talking with control room operator or inter-team communications

-

-

Step 6: Final Sedimentation

-

Water sampling: At this point, the water is nearly clear and there are few hazards. Workers may choose to use safety glasses instead of goggles.

Potential nuisance:

- Noise: ambient noise from discharge waterway; communications could be desirable for ease of talking with control room operator or inter-team communications

-

Potential 3M PPE:

- Head Protection

- Protective Eyewear

- Communication Solutions

Water sampling: At this point, the water is nearly clear and there are few hazards. Workers may choose to use safety glasses instead of goggles.

Potential nuisance:

- Noise: ambient noise from discharge waterway; communications could be desirable for ease of talking with control room operator or inter-team communications

-

Potential 3M PPE:

- Head Protection

- Protective Eyewear

- Communication Solutions

-

-

Step 7: Disinfection and Discharge

-

Final treatment: Chlorine, iodine, ozone or UV radiation may be used to destroy remaining organisms the treatment process has so far not removed before the water re-enters the environment. Workers may be exposed to chlorine or other hazardous chemicals; PPE will depend on the treatment method used.

If emergency breathing equipment is required, it should be regularly inspected and workers should be trained in its operation.

Potential hazards:

- Oxygen deprivation: emergency air supply should be available

- Chemical: inhalation of gas/fumes, skin irritation or burns from contact with liquid

- Noise: ambient noise from nearby river; communications could be desirable for ease of talking with control room operator or inter-team communications

-

Potential 3M PPE:

- Head Protection

- Protective Eyewear

- Communication Solutions

Final treatment: Chlorine, iodine, ozone or UV radiation may be used to destroy remaining organisms the treatment process has so far not removed before the water re-enters the environment. Workers may be exposed to chlorine or other hazardous chemicals; PPE will depend on the treatment method used.

If emergency breathing equipment is required, it should be regularly inspected and workers should be trained in its operation.

Potential hazards:

- Oxygen deprivation: emergency air supply should be available

- Chemical: inhalation of gas/fumes, skin irritation or burns from contact with liquid

- Noise: ambient noise from nearby river; communications could be desirable for ease of talking with control room operator or inter-team communications

-

Potential 3M PPE:

- Head Protection

- Protective Eyewear

- Communication Solutions

-

Didn't find the product you were looking for?

Training, News and Events

-

Download Resources

Download Resources -

Online Webinars - Worker Health & Safety

Online Webinars - Worker Health & SafetyNew webinars are added regularly for live or on-demand viewing

-

In-person: Training Courses and Seminars

In-person: Training Courses and SeminarsWe offer training for a wide range of common and specialist safety issues and situations.

✓ Demonstrations and seminars

✓ On-site or at 3M with accredited instructors

Expert professionals in working at heights and confined space

Tell us about the challenges you face and we will advise you on regulations and the solutions to consider for your project or sector. One of our 3M experts will get in contact with you. We are here to assist with any questions you may have and provide knowledgeable support.